Introduction

The adhesive labeling machine suits for the sticking of the self-adhesive label on the all kinds of bottle shapes (square, round, oblate, elliptical bottle). The machine used PLC programmable control, photo electricity detection label-sending, with high production efficiency, correct and smooth label-sticking, steady and reliable performance, simple operation. automatically detects the label size and bottle diameter and set the appropriate labeling parameters. Widely used in the industry of foodstuff, pharmacy, daily chemicals, pesticide and cosmetics, etc.

Technical parameter

| item | Description | |

| 2 | Labeling speed | 1500-6000bph,adjustable |

| 3 | Bottle diameter | Below 120mm |

| 4 | Label width | 10-200mm |

| 5 | Label length | 10-400mm |

| 6 | Labeler error | ≤ ±0.5mm |

| 7 | Label Roll Diameter | Reel Inner diameter: 76mm; Reel outer diameter: Max 360mm |

| 8 | Net weight | 550kg |

| 9 | Contour Sizes | 3000*1500*1700mm |

Technical Features and application:

1. This bottling and labeling machine with fast labeling speed, labeling position is accurate, running stable.

2. Large application range, can be used on different kinds of bottles, square bottle, round bottle, flat bottle, and abnormal bottle , etc.

3. Adopt flexible top press structure and guide structure, can fix bottle on the conveying belt stably, no bottle no label.

4. Easy adjust, and easy to maintain.

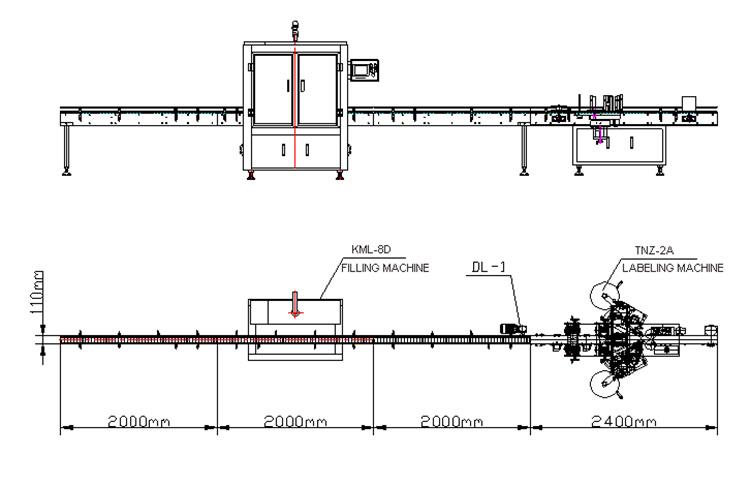

We also can provide filling machine before labeling machine, to connect to be one whole production line, below bottling and labeling machine drawing for reference.

Device Advantages:

1) Control system: American AB brand PLC control system, with high stable operation and extremely low failure rate.

2) Operation system: 10 inch touch screen, directly visual interface easy operation ,with Chinese and English two kinds language, also rich with help function and fault display function.

3) Check system:Use German LEUZE check label sensor, automatic check label station, stable and convenient don't have much higher requirement for the worker.

4) Send label system: American AB high-power servo control system, stable with high speed.

5) PARAMETER SAVE: can save 30 groups labeling parameters, when change the bottles, don't need reset parameters, just adjust the machine part is ok.

6) Alarm function: such as label spill, label broken or other malfunction during machine working all will alarm and stop working.

7) Machine Material: The machine and spare parts all use material S304 stainless steel and anodized senior aluminum alloy,with high corrosion resistance and never rust.

8) Labeling way : use the servo send label system to send label on product surface.

9) Low voltage circuit all use the German Schneider brand.

Main Electrical Configuration:

| No | Name | Model | Unit | Brand |

| 1 | PLC control system | 288-1ST20-OAAO | 1 Set | SIEMENS |

| 2 | Touch-screen | 648-OCC11-3AXO | 1 Piece | SIEMENS |

| 3 | Servo motor | 2004-RZ08BAIAN3 | 2sets | America AB |

| 4 | Drive | 2003-CSD3-08BX2 | 2sets | America AB |

| 5 | Frequency converter | 6SL3210-5BB15-5UV0 | 1 set | SIEMENS |

| 6 | photoelectric sensor (check bottle) | FS-N18N | 1 set | Japan KEYENCE |

| 7 | Photoelectric sensor (Check opaque label) | GS61/6.2 | 2 sets | German Leuze |

| Photoelectric sensor (Check opaque and transparent label) | GSU 14B/66.3-S12 | 2 sets | German Leuze | |

| 8 | Main transport motor | M2BAX-0.55KW-4P-B14 | 1 set | Switzerland ABB |

| 9 | Separate bottle Motor | 40W1:30 | 2 sets | German JSCC |