Automatic shrink sleeve labeling machine, with steam shrink tunnel and generator, PVC, PET lable machine Bottles Shrink labeling machine.

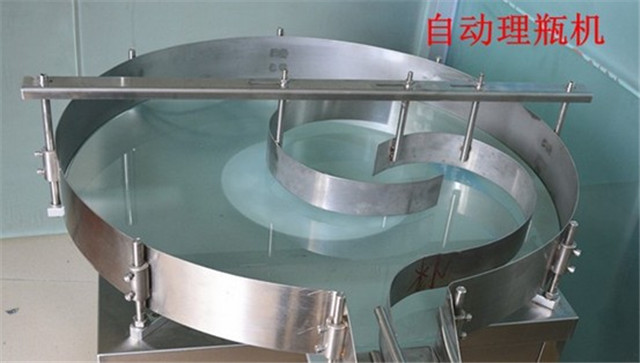

Bottles bottle unscrambler with 1.0m diameter

The Unscrambler is the driving force with frequency control table, put the bottle of artificial circular turntable, turntable rotation, will be transferred to the bottle conveyor belt has continued into the filling line for filling. Easy to use, you easily done with the bottle Unscrambler work.

Features of bottle unscrambler

1) Suitable for unscrambling disordered polyester bottles

2) Aligns bottles and discharges them by vacuum conveyor

3) PLC program controlled

4) Automatic.

5) High speed operation

Technical parameters of bottle unscrambler

* Diameter: Φ1000mm

* Speed: 430-50bottles/min(with Speed Controller, Schneider Inverter)

* Power: AC 220V±5% 50Hz 120W

* Material: SUS304

* Motor: Wanxin(Taiwan Brand, reducer without maintain)

* Variable Speed Controller: Taida

* Machine Weight: 80Kg Bottle Diameter Ø20~Ø100 mm

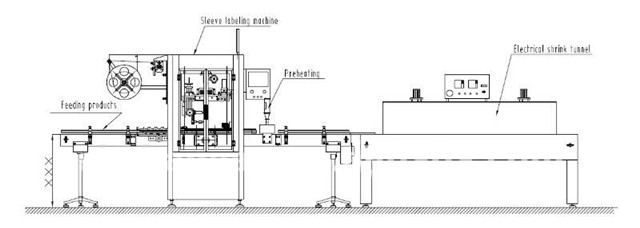

sleeve labeling machine with shrink tunnel

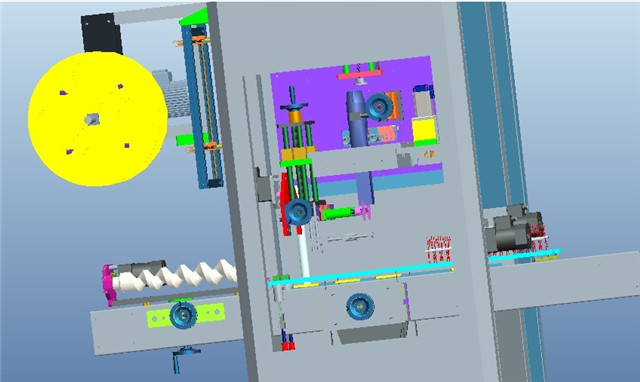

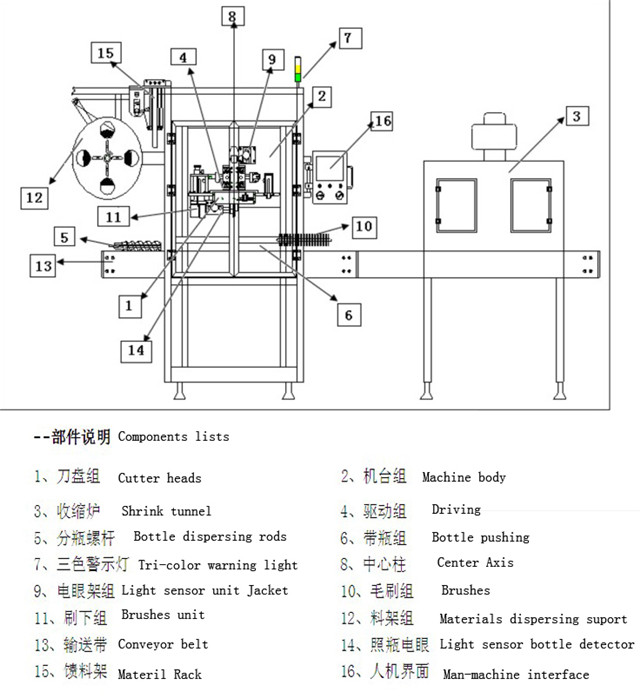

The sleeve shrink labeling machine with shrink tunnel adopts PLC programmable controller, imported servo motor, servo driver, frequency converter and transducer; also, it is equipped with the positioning module to ensure the casting label precise, rapid and stable.

1 Synchronized transmission, any change of transmission belt will be finished quickly. Compared to the type of traditional multilayer whose change and maintain need more than six hours, its maintenance is easy and maintain is simple, so it doesn’t influence production.

2 Unit cutter head plane design in China which apply to the container of 30mm—130mm.you never need to change or debug it. It also has unique light touch human-machine screen, that means,auto search original location as well as safety and convenience which is aheadof other congener products.

3 Single shrinking label feed plane ,reasonably height which is convenient to fix the label; micro-computer auto figure which avoid enactment and adjustment .you only need to press it lightly ,the label will detect and locate automatially.The change of label is quick and convinient,besides,the cut place is absolutely exact .

4 Label feeding equipment;driving synchronized tensility control the supply of label ,the supply ability is 90meters per minite,volume label supply plane is 500mm,the internal diameter of paper tube will be 4’ ,8’,10’ .the configuration of label feeding is stable tensility which enable the exact length of label and the stable, quick supply of label.

5 The center pillar applies step by step shoot label structure and the speed is 150B per minute.

6 The newly designed cutter head use step by step motor driving which speed is high, action is exact, the cut is in order and the shrinking is beautiful. This design cooperates with the label synchronized location structure enable the precision of cut location within 1mm.

7 Many emergency stop buttons enable emergency stop at the proper position along the production which guarantee the safe production.

Applicable Variety Types of Label:

Various kinds of bottle types, for example: round bottle, square bottle, flat bottle, curve bottle and cup-shaped, etc.

Main technical parameters of the sleeve labeling equipment:

| No. | Part | Item | Unit | YX-SL150 |

| 1 | Bottle specification | Volume | L | 0.35~1.5 |

| Neck diameter | mm | 28~38 | ||

| Body diameter | mm | 50~110 | ||

| Bottle height | mm | 150~310 | ||

| 2 | Label specification | Material | / | PVC PET OPP OPS |

| Thickness | mm | 0.038~0.05 | ||

| 3 | Labeling specification | Labeling speed | b/min. | 150bpm |

| Ambient temperature | .C | -10~40 | ||

| 4 | Power standard | Main power | Kw | 3 |

| Voltage | V | 210~250VAC 50hz | ||

| 5 | Conveyor specification | Inlet conveyor | m | 2 |

| Bottle conveyor | m | 7 | ||

| 6 | Dimension | Main machine dimension L*W*H | mm | 2000*1100*2100 |

| Weight | Kgs | 350 | ||

| 7 | Production rate | 0.5L/1.5L | bph | 5000~8000bph |

Shrink tunnel parameter

shrink machine size: 2100*850*2000mm

steam pressure: 1kg/cm2

steam: 50kg/h

steam furnance size: 2000*500*1700mm

Sleeve shrink labeling final products samples

Sleeve shrink labeling final products samples

Guarantee: for all the machine, it claims one year for guarantee.(Excluded from the warranty are problems due to accidents, misuse , misapplication, storage damage, negligence, or modification to the Equipment or its components.

Installation: after the machine arrive your factory,if you need,our technician will go to your place to install and test the machine and also training your worker to operating the machine (The time of train depend on you worker). The expenses (air ticket ,food , hotel,the travelling fee on your country) should be on your account and you need paid for the technician USD100 per day. also you can go to our factory to do training.

After service: If you get the problem on the machine ,our technician will go to your place to fixed the machine as soon as possible. The cost should be in your account.