Introduction

This labeling machine for plastic bottles suitable for label wrap around the bottle or half around, can match with automatic bottle arrange, also connected with filling and capping machine by conveying belt.

Process:

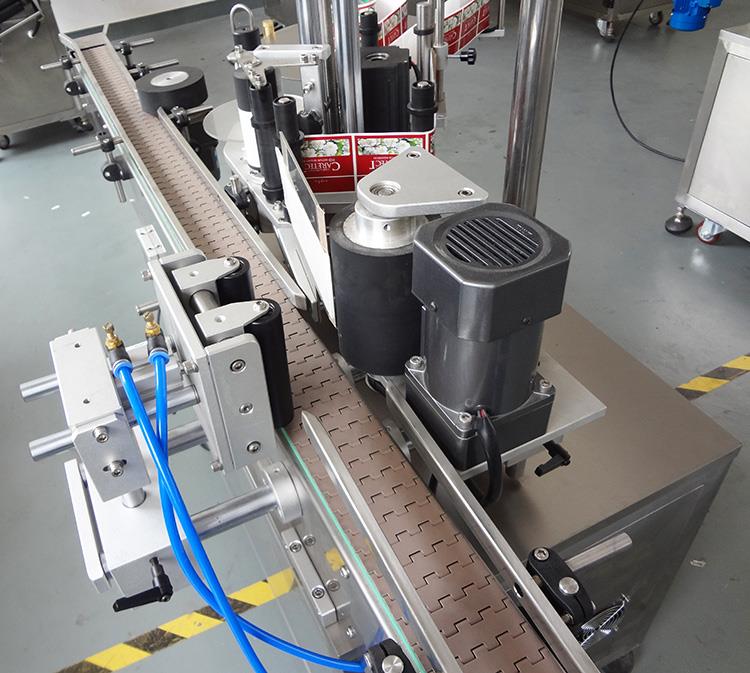

Put bottles(can connect with production line)—product conveying—separate product—product detect—labeling—attach film, connected labeling product.

Cylinder position, bottle body 3 points position, round bottle labeling, avoid error, more accurate labeling, special taper bottle can customized.

Technical parameter

| item | Description | |

| 2 | productivity | 40-150 bottle/min( relate to material and label size) |

| 3 | Conveyor width | 80mm(Could be customized) |

| 4 | Conveyor height | 1050mm(Could be customized) |

| 5 | direction | from left to right(Could be customized) |

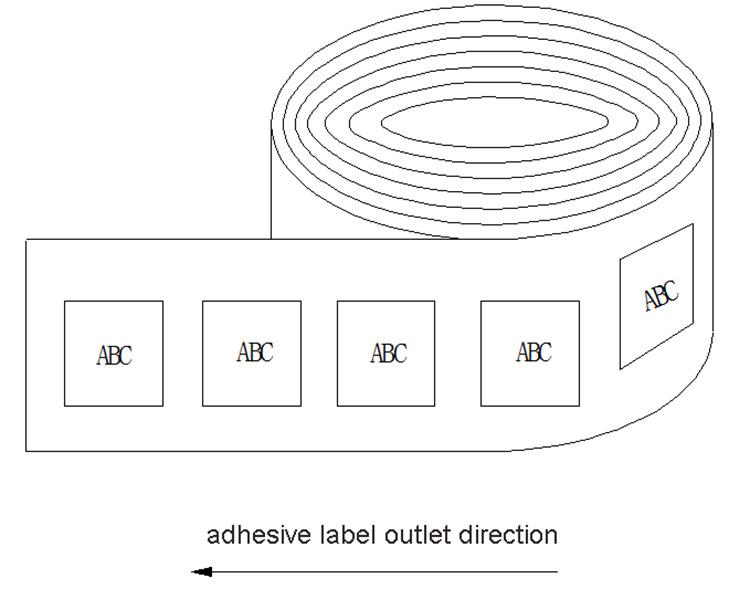

| 6 | Roll inside(mm) | 76mm |

| 7 | Roll outer side diameter(mm) | 350mm |

| 8 | Label size | (L)20-200mm (H)10-184mm |

| 9 | Material size | (L)30-200 (W)40-180 (H)40-260mm |

| 10 | Labeling accuracy(mm) | ±1mm |

| 11 | Power supply | AC220V 50Hz/60Hz 1200W |

| 12 | Net weight | 350kg |

| 13 | Contour Sizes | 2000*1400*1700mm |

Technical Features and application :

1. PLC combined with LCD touch screen panel, parameter setting and operation is clear and easy.

2. The equipment is complied with GMP requirements and made of SUS304 stainless steel and High-class aluminium alloy

3. Famous brand electrical components assure the labeling accuracy

4. The conveyor is controlled by convertor, speed setting is very easy.

Application range:

1. Suitable label: adhesive label, adhesive film, electronic supervision code, bar code etc.

2. Suitable product: label or film attached on circumference surface.

3. Application industry: foods, medicine, cosmetic, chemicals, etc.

4. Suitable: PET bottle, plastic bottle, cans etc.

Main Features

1) Wide application range, can meet the needs of all round bottle labeling or semi circle labeling, labeling switching between the bottle is simple, easy to adjust

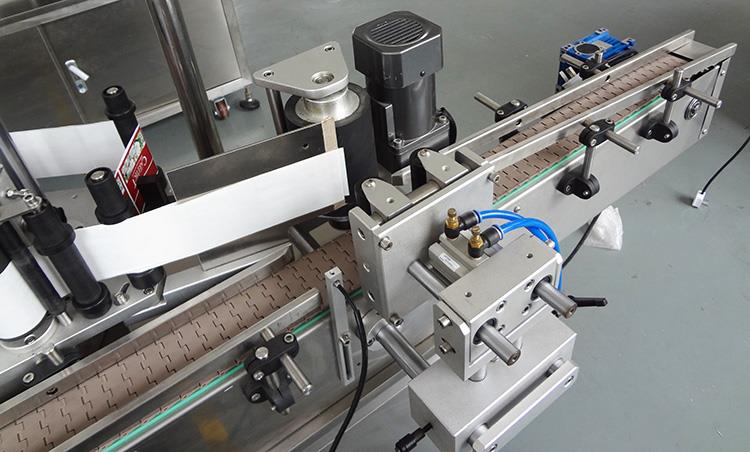

2) The label accuaracy is good, the tape detour adopts the rectifying mechanism, the tape does not deviate, the three directions of the labeling position x / y / z and the inclination are adjustable with eight degrees of freedom, and the adjustment has no dead angle.

3) The label quality is excellent, adopt the elastic press cover belt, the label is flat, no wrinkle, improve the packing quality.

4) The application is flexible , the bottle standing type labeling machine is provided with an automatic bottle separating function , can be produced in a single machine , and also can be connected with the production line.

5) Intelligent control , automatic photoelectric tracking , non - labeling , non - standard automatic correction and label auto - detection, prevention of leakage and label waste.

6) High stability, The supporting equipment runs 7 × 24 hour, Mitsubishi PLC, SIEMENS Touch , KEYENCE bottle sensor, Leuze high accuracy label sensor.

7) The adjustment is simple , the labeling speed , the conveying speed and the bottle separating speed can realize stepless speed regulation , and the adjustment is carried out according to the requirement.

8) Strong and durable, adopt three bar adjusting mechanism, make full use of the stability of triangle, the whole machine is solid and durable. It is made of full ss304 stainless steel, which is in line with the requirements of GMP production.