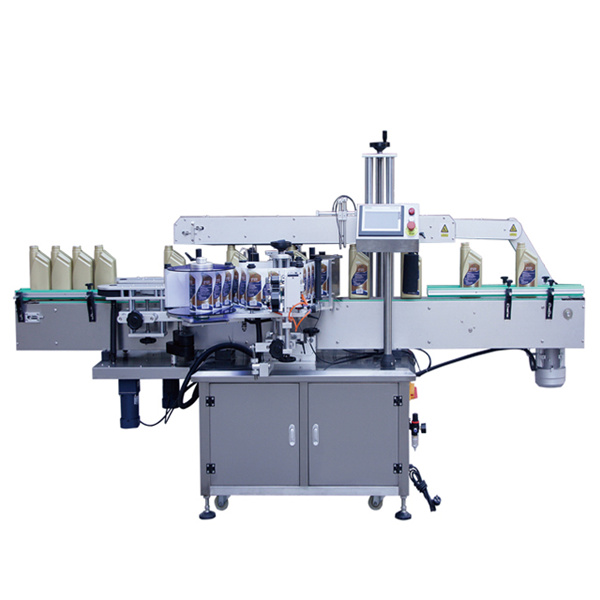

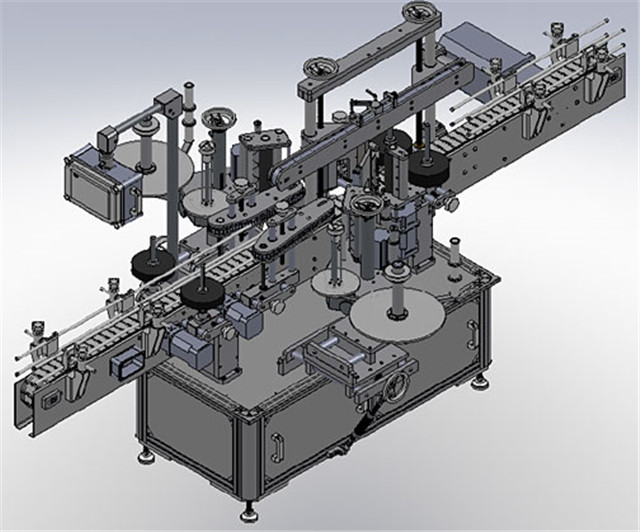

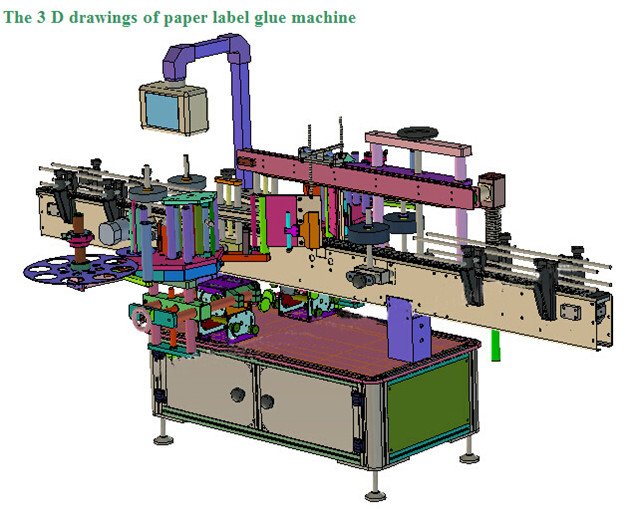

The whole double sided labeling machine adopts elaborate DIY design. By eliminating unnecessary complex and heavy machinery, it adopts suit type assembly. The maintenance and servicing can be completed without professionals. When it is necessary to replace the product, just make some simple adjustments, it can be immediately put online for production.

The whole machine is made of S304 stainless steel and high class aluminum alloy using anodizing treatment.

The labeling head is driven by advanced stepping motor Imported from Japan.

All electric eyes are Japanese or German advanced photoelectric eyes.

PLC large-scale human machine interface control, allocated with 60 groups of memory units.

The machine labeling equipment automatic , provided with such mechanism as bottle Piloting, bottle dispensing and labeling, and counting etc,is most suitable for use of small amount of various products or for operation of single machine and single person.

The labeling position, height and angle can be adjusted. It can be connected by conveying belt with the production line.

Applications

It is suitable for labeling various round bottles (tanks) in such industries as food, condiment, medicine, wine, oil and cosmetics etc.

Characteristics:

1. Adopt mature PLC control system technology, make the whole machine stable and high-speed

2. Can be suitable for square /round/oval flat bottles at the same time

3. Use touch screen control system, make operation simple, practical and efficient

4. Upgraded butterfly labeling station design, can be applied for conical bottle labeling

5. Screw adjust the suppression mechanism, high accuracy

6. Synchronization chain mechanism, to ensure smooth and precise calibration

7. Transparent sticker labeling without foam,adhesive sticker labeling without wrinkle

8. Widely used and mutil-function with high flexibility

9. Date/code printer is for optional

10. Tranparent label sensor is for optional

11. Can be customized according to your requirement

Electronic components with brand

| Item | Name | Brand | Quantity |

| 1 | PLC | MITSUBISHI | 1 |

| 2 | Frequency changer | DANFOSS | 1 |

| 3 | Touch screen | WEINVIEW | 1 |

| 4 | Servo labeling motor | DELTA | 2 |

| 5 | Servo labeling motor drives | DELTA | 2 |

| 6 | Conveyor motor | DWG | 1 |

| 7 | Conveyor belt motor gear box | DWG | 1 |

| 8 | Separating bottle motor | GPG | 2 |

| 9 | Separating bottle motor gear box | GPG | 2 |

| 10 | Electric eye for checking bottles | OMRON | 1 |

| 11 | Optical | OMRON | 1 |

| 12 | Label detection electric eye | LEUZE | 2 |

| 13 | Label stock electric eye | OMRON | 2 |

Main Technical Parameters

| Voltage | 220V, 50HZ |

| Power | 2KW |

| Labeling Speed | 20-120bottles/min, 150-200bottle/min |

| Labeling Accuracy | ±1mm |

| Printer to use air | 5 kg/cm2 |

| Object Size | 30-200 mm(H),30-100 mm(W) |

| Label Size | 25-300 mm(L),20-180 mm(W) |

| Roll Size | 76 mm(Inside),380 mm(Outside) |

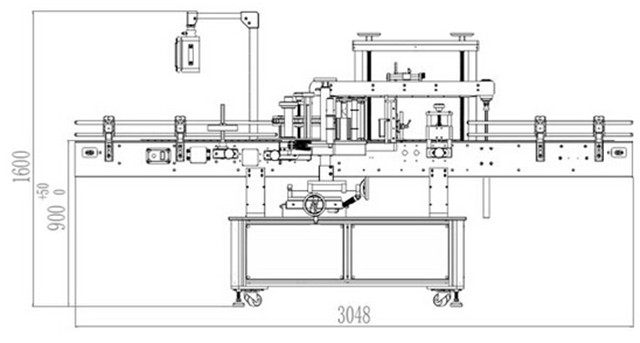

| Dimension | 3048(L)×1500(W)×1600(H) mm |

Installation Services

Installation Services are available with all new machine purchases. We will provide the technical know-how for your operation smooth transition and support for installing, debugging, operation of the machine, it will indicate you how to use this machine well.

After Sales Service

We offer the Preventative Maintenance and After Sales Service. For we strongly feels about the importance of supporting our customers and the product solutions we provide. Consequently we offer comprehensive maintenance options to prevent equipment issues before they become problems.

Training Services

We can train your staff to use our machine properly. It means that we offer Customers Training, teaching how to use the systems most efficiently and safely as well as how to maintain optimal operational productivity.