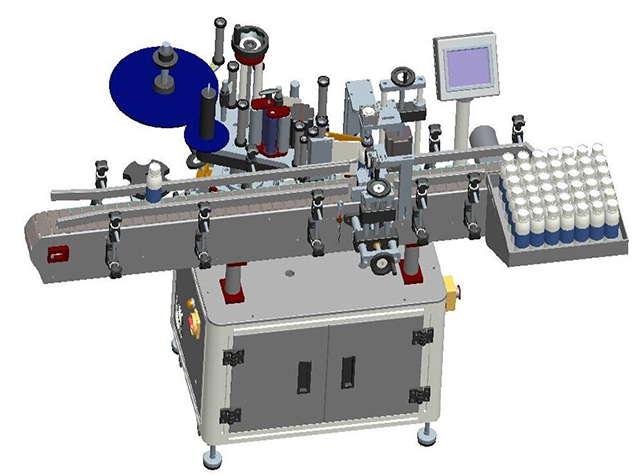

The whole set of labeling machine that can be used for various cylinder form product Semi circumreference, just the back double mark sticks a mark, such as sticking of food can, cosmetics circle bottle, and medicine bottle...etc. mark;Take a dozen of code machines such as the another nuance, can carry out to stick a mark to print to produce information like batch number,etc at the same time.

Application

*Apply label: The not dry gum label doesn't do a gum film, the electronics takes charge of code, the form code wait;

*Apply a product: The product that requests to stick to attach label or film on the circumference noodles, conic surface;

*Applied profession: Extensively Be applied to a food, medicine, cosmetics and day to turn, electronics, hardware, plastics etc. profession;

*Is applied solid example: The PET circle bottle sticks a mark, the plastics bottle sticks a mark, food can etc.

Technique parameter:

*Stick to mark accuracy: ±1 mm;(do not contain a product, label error margin)

*Stick to mark speed: Is 20~60|minute;(have relation with product label size)

*Apply product size: ¢ 30 the ≤ product diameter ≤¢ 100 mms;

*Apply label size: 15 ≤ width ≤ 110 mmses, length ≥ 20 mms;

*The whole machine size: 1800 ×s 900 ×s 1300 mmses;(long × breadth × height)

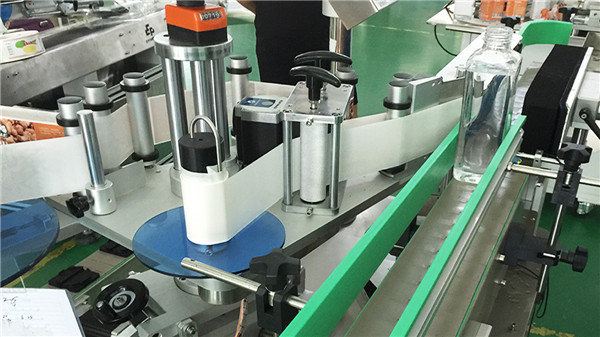

*Apply the power: 220 Vs 50|60 Hzs;

*Air pressure: 0.2~0.5 Mpas;

*The whole machine weight: 280 kgs.

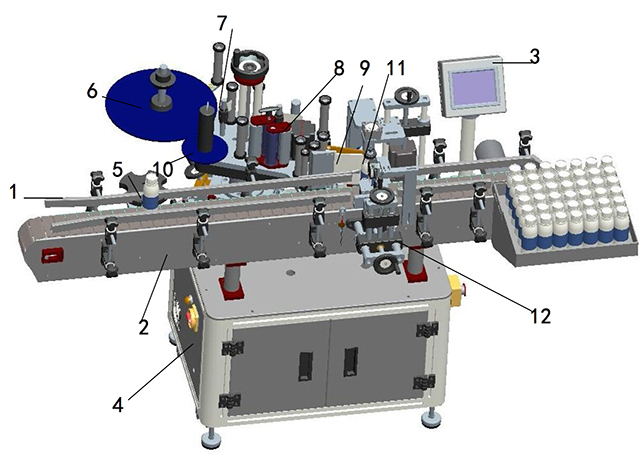

Drawing of labeling machine:

Details illustration of labeling machine

1. Guide bar: Guide the product moving along the belt;

2. Delivery system: Delivering the bottles to the labeling part and to the collector table after labeling;

3. Touch screen: HMI,change the parameter to control the ma

4. Electric box: Electronic controlling center,various controllers and PLC arrayed;

5. Bottles distrituting system: adjust the delay time by adjusting the motor to get the proper time for labeling different bottles;

6. Labels Plate: Labels supporting part;

7. Labels pressure:Tighten the labels,keep the tension of labels in order to label the products accuractly;

8. Traction system: Motor driving the label paper to empower the labels peeling;

9. Labels peeling plate: Peel the labels;

10. Labels collector: recollecting the bottom labels paper;

11. Labels covering: Perfect the labeling effect;

12. Positioning system: Articles positioning system;

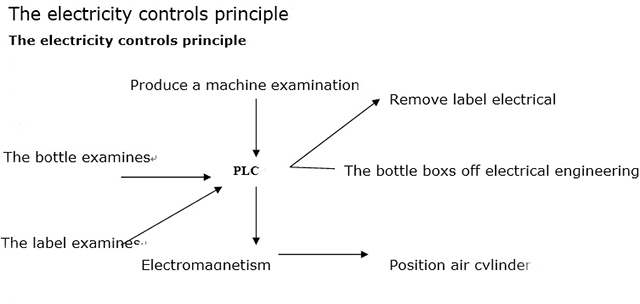

The electricity controls principle

Pass a product examination and stick mark examination, label to examine three types of importations of signals, after PLC processing after, exportation in order to lead the control signal of electrical engineering, electromagnetism valve, control flexing of air cylinder and lead turning of electrical engineering respectively, complete the fixed position of product to stick mark to act thus.