Application :

Widely used in food chemical medical cosmetics electronics, hardware automotive parts, stationery, cardboard boxes surface labeling, product shaping or not, surface rough or not all ok.

1. This series of products are not only suitable for the s round can/jar/cylinder/bottle in pharmaceutical, pesticide, food & chemical industries.

2. It can automatically finish bottle-grouping, sending mark tape, separating labels synchronously, labeling and automatically printing batch number etc.

3. With mechanics technology, it adopts big torque motor to drive, and imported photoelectric control & PLC program control system, thus guaranteeing accurate labeling, stable, reliable and high efficiency.

Peration control system:

World famous brand PLC and servo system, multifunctional man-machine interface operation production count, visual monitoring of parameter adjustment help function and fault display show function, can preset many group labeling parameters, Change bottle no need re-setting, Detect label length automatically.

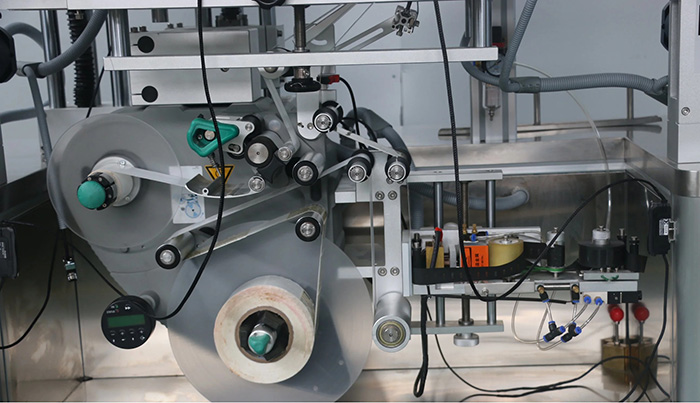

Details

Features:

1. The whole machine and spare parts use international standard SUS304 stainless steel imported alloy material. double anodic oxidation treatment, with high corrosion resistance and never rust, suit for any production environment.

2. German import labeling engine is optional, advanced self-adaption labeling control system, reduce and simplify operating and adjusting ,improve efficiency, After change products or label, made simply adjustment is ok, do not have much requirements for worker skill.

3. Transparent label no bundle, self adhesive label no wrinkle.

4. With clamp device ensure labeling position, greatly improve labeling accuracy.

Device Advantages

Imported electric elements, stable performance, low failure rate;

Adopting photoelectric detection, PLC control, software operation, conveyor belt, labeling accurately and high precision;

Can be operated alone or contract with the production line;

No bottle not labeling, automatic alarm when achieve leakage label.

The whole machine use the material of S304 stainless steel and anodized senior aluminum alloy.

Technical parameters:

| Label objects size | Width:60-350mm .height :60-380mm |

| Label size | Length 10-300mm,Height 10-70mm |

| Labeling speed | 50-200pcs/min |

| Labeling accuracy | +/-1.0mm |

| Label roll diameter | Inner diameter 76mm Outer diameter :350mm(MAX) |

| Labeling type | Adhesive sticker, transparent or opaque |

| Voltage | 220V +-10%,50HZ.2.0KW |

| Air pressure | 0.6Mpa |

| Applicable environment | Temparature 5-40,humidity 15-85%(no condanansation) |

| Weight | 200kg |

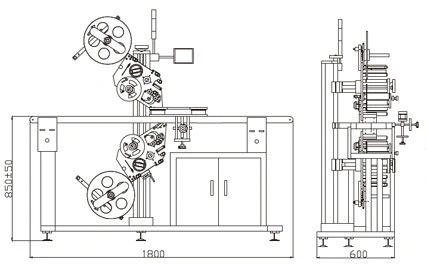

| Dimension | L1800*W800*H1500mm |

| Remarks | Can customized as client need |

Sketch Map:

Optional:

1. Thermal transfer printer(TTO) or link jet coding is optional.

2. Opaque or transparent labeling material all ok.

3. Automatic feeding mechanism and vacuum adsorption conveyor belt.

4. Top labeling or bottom labeling or top and bottom labeling can choose as client product labeling need.