Introduction

This square bottle labeling machine is equipped with computer touch screen which layout very large scale integrated circuit. it is controlled by micro-computer with Chinese character touch screen, realized the man-machine communication. Micro-computer configuration is helpful for all data input by touch screen and also for all-round control the running condition once machine started.

PLC round adhesive labeling machine is the upgrade product of out company which have simple and reasonable structure and easy for operation. The production can be adjusted by the specification and feature of bottles and labels. it's fit for all kinds of bottles. Both transparent adhesive sticker and non-transparent adhesive sticker can be well label on the bottles or containers whatever are glass bottles or plastic bottles which used in food, machine or cosmetic field.

Technical parameter

| Labeling speed | 30~120 Bottles/minute(Depends on the container size and label length) |

| Container outside diameter | 20~120mm |

| Container Height | 35~200mm |

| Label Length Range | 233~200mm |

| Label height range | 15~90mm |

| Labeler error | ≤ ±0.5mm |

| Label Roll Diameter | Reel Inner diameter: 76mm; Reel outer diameter: Max 360mm |

| throughput direction | Left → Right |

| Net weight | 650kg |

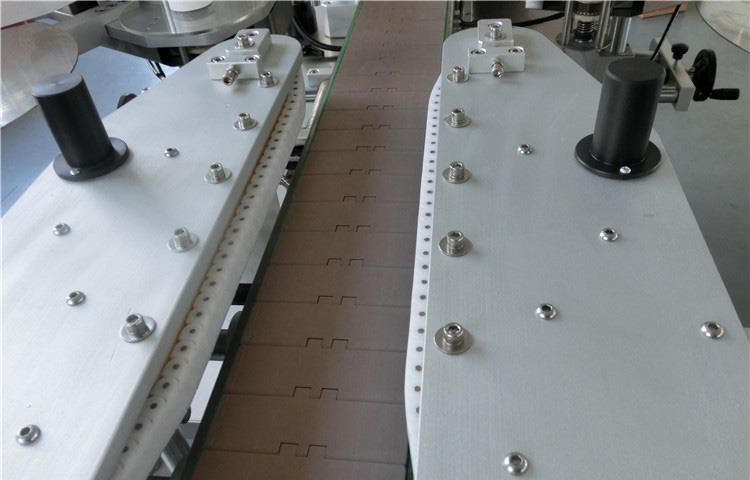

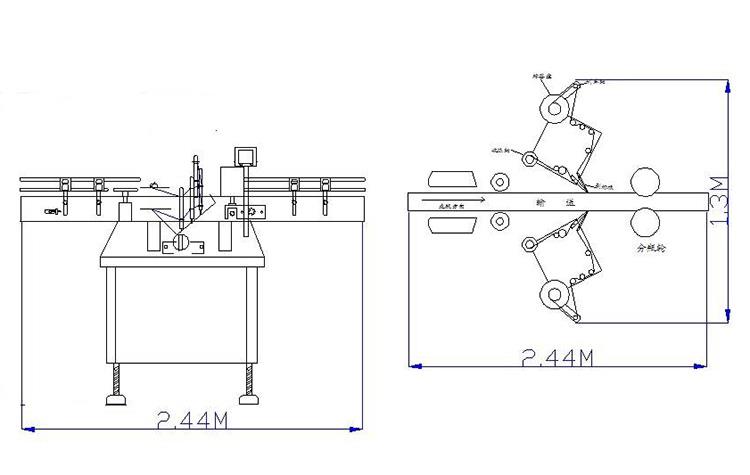

| Contour Sizes | 2400mm*800mm*1370mm |

Technical Features and application :

1. specification of label's reel :diameter of label's reel is ≤350mm,maximum width is 90mm,diameter of hole of reel is 75mm.

2. operating temperature: 5~35℃

3. Operating Humidity:30%~80% RH

4. Operating environment:No flammable and explosive gas and dust

Working principles:

Controller will start the transfer label stepper motor and transfer label out quickly once it detect bottles need to be labeled via bottle position senor, and with scrolling label motor together. The transferring label operation will be stopped once it detect there's gap between labels, at this moment , coding signals is sent out. And controller counted our labeled bottles and refresh the data and show on the screen .And the controller also monitor all parameter settings and alarm on time to control machine's running.

1. This series of products are not only suitable for the s round can/jar/cylinder/bottle but also flat square two sides bottles in pharmaceutical, pesticide, food & chemical industries.

2. It can automatically finish bottle-grouping, sending mark tape, separating labels synchronously, labeling and automatically printing batch number etc.

3. With mechanics technology, it adopts big torque motor to drive, and imported photoelectric control & PLC program control system, thus guaranteeing accurate labeling, stable, reliable and high efficiency.

- With micro-computer labeling system, fast & stable, suitable for longtime work with system check function: labels lacking or broken, leaving out, e-stop, abnormal frequency-conversion, typewriter ribbon lacking, it can detect all & then stops auto.

- The I/O self-check function, can display all system photoelectric signals & motor, shorten repair time, reduce maintenance cost.

- With step less speed control, labeling speed automatically changes according to conveying speed, no need to move labeling sensor.

- Made of SUS304 & alumni alloy, totally meeting GMP requirements.

1. What kind of labeling machine do you have?

Dear Customer, we have automatic and semi-automatic labeling machine for round containers and flat surface. Some model for one label and others for two labels or even more. And we can design the machine according to your specific labeling situation.

Thus, pls fell free to send us your labeling requirements, we'll provide you satisfying labeling solution.

2. Could we add coding machine to print date and lot No.?

Yes, you can chose to add coding machine to print the letters and No. you want. It's hot stamp and can print at most three lines.

3. What information should we supply to check the suitable model?

Pls send us picture of your container and label, as well as the container and label size.

Pls also tell us what kind of label you use, if possible. (For exampe, self-adhesive, could glue, hot glue, etc. whether the label are in roll or pieces.)

Then, we'll let you check the suitable model.