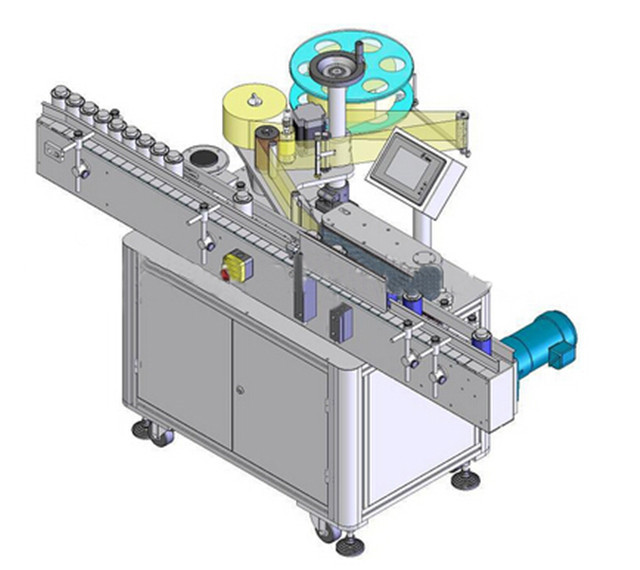

Basic using of model Round bottle labeling machines:

For the pharmaceutical, food, cosmetic and other industries round bottle labeling, can be affixed to the week and semicircular labeling labeling.

Optional automatic turntable Unscrambler can be directly connected to the front end production line, automatic feeding bottle into the labeling machine, increasing efficiency.

Optional configurations ribbon coding labeling machines, online print production date and batch number, reduce bottle packaging processes, improve production efficiency.

Application of labeling machine round bottle labeler:

For label: self-adhesive labels, self-adhesive film, electronic supervision code, bar code, etc.

Application: require circumferential surface of the membrane attached label or product.

Industry: Widely used in food, medicine, cosmetics, cosmetic, electronic, metal, plastics and other industries.

Application: PET round bottle labeling, labeling plastic bottles, canned food and so on.

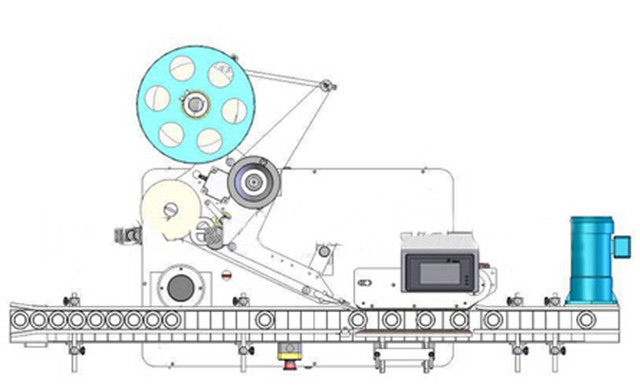

* Core works: the product of bottle body separated, the sensor detects the product passes the signal returned to the labeling control system, the control system in place to control the motor sends label affixed to the product subject to labeling and position, product flow the standard unit cover, covered with standard rotation driven products, the label is roll coating, a label attached to the action is completed.

* Procedure: put the product (which can be accessed line) -> product transfer (device automatically) -> Products minutes away -> Product Testing -> Labeling -> cover marked -> collect the labeling products.

Technical parameters

The following technical parameters for the standard model, other special requirements and functions can be tailored

Suitable label length (mm): 20mm ~ 314mm

Applicable Label width (backing paper width / mm): 15mm ~ 150mm

Applicable Products diameter (for round bottle) and height: diameter: φ25mm ~ φ100mm

Height: 25mm ~ 230mm

Applicable standard roll diameter (mm): φ280mm

Applicable standard roll diameter (mm): φ76mm

Labeling accuracy (mm): ± 1mm

The standard speed (m / min): Servo: 5 ~ 25m/min

Stepping: 5 ~ 19m/min

Labeling speed (pcs / min): Stepping: 30 ~ 80pcs/min (with the bottle and label size)

Servo: 40 ~ 120pcs/min

Conveyor speed (m / min): 5 ~ 25m/min

Weight (kg): about 185kg

Frequency (HZ): 50HZ

Voltage (V): 220V

Power (W): 530W (traction stepper) / 980W (traction servo)

Device dimensions (mm) (L × W × H): 1950mm × 1100mm × 1300mm

Features from round bottles labeling machine automatic:

♦ Wide range of applications, which can meet the entire circumference of round bottle labeling or semi-circle label, bottle label switching between simple and easy to adjust;

♦ Labels coincide high standard with bypass adopt corrective institutions, marked with no easy road, labeling parts of the x / y / z direction and the inclination of eight three degrees of freedom is adjustable, adjust no dead ends, labels coincide with high ;labeling quality, using standard belt cover sexual repression, labeling smooth, wrinkle, improve the quality of packaging;

♦ Flexible, stand-labeling bottles, bottles with automatic function, stand-alone production, can also be connected to production line;

♦ Intelligent control, automatic photoelectric tracking, with no object no labeling, no label auto-correction and auto-detection function labels, stickers and labels to prevent leakage of waste;

♦ High stability, Panasonic PLC + touch screen + Panasonic Matsushita Electric eye needle + German Leuze label sensor composed of advanced electronic control systems, support equipment 7 × 24-hour operation;

♦ Adjustment is simple, labeling speed, transmission speed, divided bottle can realize stepless speed, adjust as needed;

♦ Rugged, using three adjustment mechanism, take advantage of the stability triangle, the whole solid and durable.

♦ Stainless steel and high-alloy steel, meet GMP production requirements;

Optional features:

1. hot coding / marking function;

2. automatic feeding function (combination of product considered);

3. automatic rewinding function (combination of product considered);

4. increased labeling devices;

5. circumference circumferential positioning labeling function;

6. Other features (according to customer requirements) .

| No | Name | Model | Unit | Brand |

| 1 | PLC control system | 6ES7212-1A | 1Set | SIEMENS |

| 2 | Touch-screen | 6AV6648-01A | 1Set | SIEMENS |

| 3 | Photoelectric sensor (Check bottle) | FS-N18N | 1Set | Japan KEYENCE |

| 4 | Photoelectric sensor (Check opaque label) | GS61 | 1 Set | German Leuze |

| 5 | Servo motor | 2004-RZ08BAIAN | 1Set | America AB |

| 6 | Drive | 2003-CSD3-08BX2 | 1Set | America AB |

| 7 | Main transport motor | 90W1:30 | 1Set | German JSCC |

| 8 | Press bottle motor | 40W1:30 | 1Set | German JSCC |

| 9 | Speed Controller | 25-90W | 2sets | German JSCC |

Machine Structure:

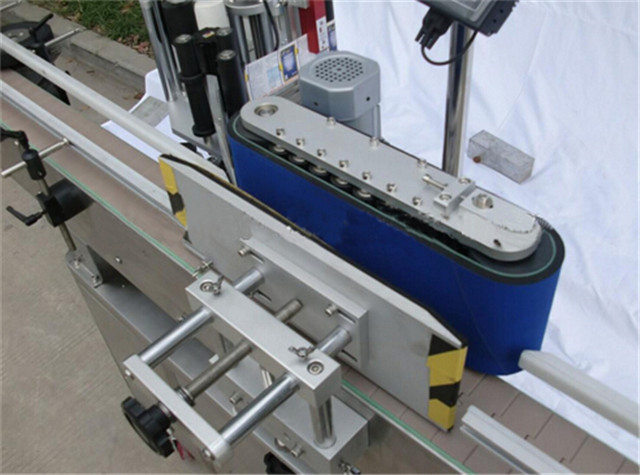

Belt Type Conveyor

This labeler use imported industrial belt. It is much wearable without dirty easily and for long term life operation. It also could change over the suitable belt material depends on products.

Precise Sensor

Adopt to top level fiber optic sensor to precisely do products and label location without interference. Unique design for slide rail, it is much different from the poor design by general manufacturer.

Quality & Beauty

The labeler main structure is manufactured from S304 stainless steel with anodized process and high quality aluminum. It is complied with GMP standard that provides easy maintenance and for a long durable life. Top chain made by FRP chain material and hard-wearing UPE guide rail applied for the conveyer system is designed to be the product appearance protected and efficient performance. It also increases with years of reliable long term use.

Simple Mechanism Adjustment

It provides a little or big wide adjustment by equipped with hand wheel mechanism for easy adjustment of applicator. It would also provide flat and smooth labeling depended on product sizes and labeling position by suitable wrap station adjustment.

Rigid Machine Base

Double square foot stands was made from stainless steel. It is steady and does not take a lot of room. When labeler working, it would not quake and affect the labeling action.

Flexible Mobility

The mobility castor and stainless steel fixing nut are designed to flexibly move the machinery to support another production line. Therefore, it would boost the invest benefits.

Package: Each machine wrapped by PO film, then packed to standard wooden case.

Production Lead: 20 workdays after getting the down payment 30%,the other 70% payment collected before shipping

Guarantee: for all the machine, it claims one year for guarantee.(Excluded from the warranty are problems due to accidents, misuse ,

misapplication, storage damage, negligence, or modification to the Equipment or its components. ALSO THE EASY BROKEN SPARE PART IS NOT INCLUDED IN THE GUARANTEE)

Installation: after the machine arrive your factory,if you need,our technician will go to your place to install and test the machine and also training your worker to operating the machine ( The time of train depend on you worker). The expenses (air ticket ,food , hotel,the travelling fee on your country) should be on your account and you need paid for the technician USD100 per day. also you can go to our factory to do training.

After service: If you get the problem on the machine ,our technician will go to your place to fixed the machine as soon as possible. The cost should be in your account.